Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

ALULARIS consultants, specializing in the aluminium extrusions industry, provide interim management services to businesses looking for expert guidance and leadership during transitional periods. Whether it’s due to a sudden vacancy, a specific project, or a company restructuring, We offer tailored solutions to help organizations achieve their objectives. With over 30 years of experience in the industry, ALULARIS brings a wealth of knowledge and expertise to each engagement, ensuring a smooth and successful transition for everyone involved.

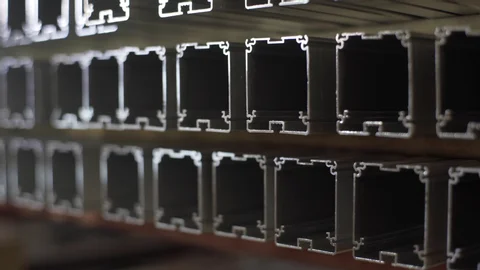

Aluminium extrusion is a process that involves shaping aluminium into various designs and sizes by pushing it through a die. This method is used in the processing, forming, and manufacturing of aluminium systems, which find application in construction, transportation, and more. Extrusions come in different shapes, including standard profiles like angles and channels, as well as custom-made designs. The aluminium extrusion process is suitable for producing large quantities of complex shapes that are strong, lightweight, corrosion-resistant, and easy to assemble. Moreover, aluminium is highly recyclable, making it an eco-friendly choice for sustainable manufacturing.

We provide technical and strategic consulting services to companies operating in the aluminium industry. Our team of experts offers insights and recommendations on a range of topics, including production processes, supply chain optimization, cost reduction, market trends, and sustainability. By leveraging our industry knowledge and experience, we help our clients to achieve operational efficiencies, identify growth opportunities, and navigate the challenges of a rapidly evolving global market. Our customized solutions are tailored to each client’s unique needs and goals, ensuring a targeted approach that delivers measurable results.

Operation and project management involve the planning, implementing, and controlling of various processes and activities to achieve specific objectives. Operation management mostly focuses on the day-to-day activities of an organization, including manufacturing, supply chain management, and quality control. Project management, on the other hand, is more focused on a specific goal or objective and involves planning, executing, monitoring, and closing a project. Both operation and project management require effective communication, resource allocation, risk management, and problem-solving skills to ensure successful completion of goals and objectives.

The aluminium fabrication industry can improve its operations by implementing technologies that improve efficiency, such as computer-aided design (CAD) and automation. Regular maintenance of machinery and equipment, staff training, and use of lean manufacturing principles are also essential in streamlining operations. The adoption of sustainable practices, like recycling scrap aluminium, can also reduce costs and improve the industry’s ecological footprint. Overall, implementing such improvements can enhance productivity, reduce lead times, and help the industry meet the rising demand for aluminium products.

This manufacturing process involves the use of lean principles to minimize waste and maximize efficiency in producing high-quality aluminum extrusions. Key components of this process include consistent quality control, standardized work methods, and continuous improvement initiatives. The focus is on eliminating non-value-added activities and streamlining processes to ensure maximum productivity and profitability. This approach helps to reduce costs, increase throughput, and improve customer satisfaction by delivering high-quality products on time and within budget.